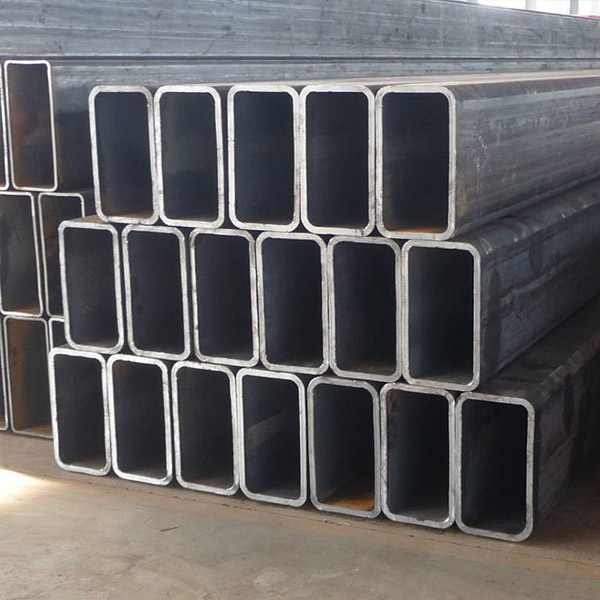

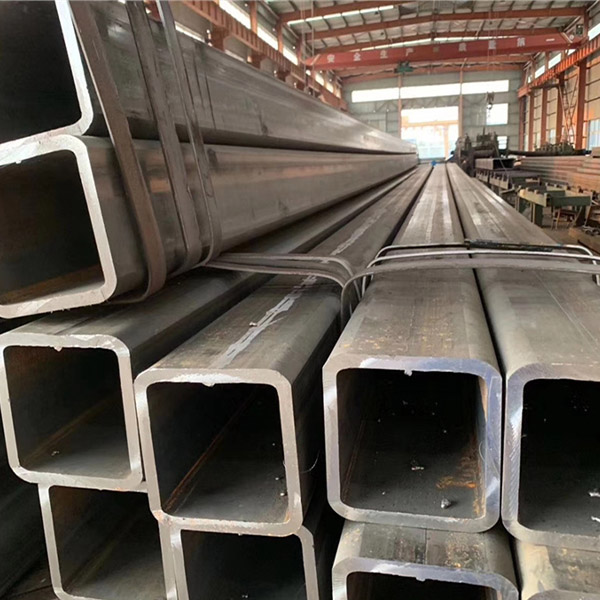

Weled Square Tube

hana ʻia ma Kina

Noi: paipu paila,

Inā pili ka pipeline me ka alloy: non-alloy

ʻAno ʻāpana: square

Paipu kūikawā: API

ʻO ka mānoanoa o ka paipu: 1.5-60

Lapaʻau ʻili: pena ʻeleʻele

Hoʻomanawanui: ±1%

Nā lawelawe hana: kulou, wili, kuʻi, ʻoki

Mea: Q195/Q215/Q235/Q345/10#/20#

Ili: pena ehu ʻeleʻele

Kinohi: paipu huinaha

Hoʻopili: hoʻopili maʻamau

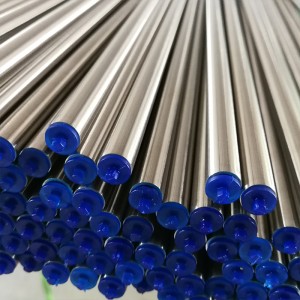

Hua'ōlelo: paipu kila maʻemaʻe

Ka manawa hoʻouna: 7-15 mau lā

Paipu kila i loko: ʻāpana ʻeleʻele

Ka nui kauoha liʻiliʻi: 1 tona

Ke kumu: Hale kūkulu

ʻenehana: Hoʻowili wela

Hōʻoia: API

1. Welded huinahalike paipu mea he hakahaka huinahalike kila huinahalike paipu, no hoi i ikeia he puha anu-hana kila. Hoʻokumu ʻia ia e ke kuʻi anu a me ke kuʻekuʻe kiʻekiʻe ma hope o ka ʻōwili wela a i ʻole ka ʻōwili ʻia a i ʻole ka coil e like me ke kila Pāhaʻi ʻia me ke ʻano ʻāpana kea a me ka nui.

Ma waho aʻe o ka mānoanoa o ka pā mānoanoa o ka pā mānoanoa pāhaʻi paipu, ka nui kihi a me ka lihi flatness hiki a oi aku paha i ka pae o ke kū'ē welded anu-hana huinaha paipu. Aia ka nui o ka huina R ma waena o 2 manawa a 3 manawa o ka mānoanoa o ka pā. .E like me ka makemake o nā mea kūʻai, hiki iā mākou ke hana i nā paipu huinahā R-angle o ka nui i makemake ʻia e nā mea kūʻai;

2. 'O ka paipu huinahā like 'ole he kaula kila lō'ihi me ka 'āpana puha a 'a'ohe ami ma ka 'ao'ao. He paipu huinaha ia i hana ʻia ma ka hoʻokuʻu ʻia ʻana o ka paipu ʻole ma o nā ʻaoʻao 4 o ka poʻi. He ʻāpana hakahaka ka paipu huinahā a hoʻohana nui ʻia. Hoʻohana ʻia ia i ka lawe ʻana i ka wai, kākoʻo hydraulic, mechanical structure, medium and low pressure, high pressure boiler tube, heat exchange tube, gas, petroleum a me nā ʻoihana ʻē aʻe. ʻOi aku ka ikaika ma mua o ka welded a ʻaʻole e pohā.

1. Kaʻina hana o ka paipu aniani hoʻomaʻemaʻe:

Tube blank-inspection-peeling-inspection-howela-perforation-pickling-wili-lubrication a me ka ea maloʻo-weld poʻo-anu huki-solution lapaʻau-pickling-pickling Passivation-inspection-anu ʻolokaʻi-degreasing-cutting-ea maloʻo-loko polishing -waho polishing-inspection-marking-finished product packaging.

2. Kaʻina hana paipu ʻoihana

Tube blank-inspection-peeling-inspection-heating-perforation-pickling-grinding-lubrication a me ka ea maloʻo-weli poʻo-anu huki-solution lapaʻau-pickling-pickling Passivation-inspection.

3. Kaʻina hana o ka paipu welded

Uncoiling-leveling-end shearing a welding-looper-forming-welding-loko a me waho bead removal-pre-correction-induction heat treatment-sizing and straightening-eddy current testing-cutting ——Hydraulic pressure inspection——Pickling——Final inspection ——Papa.

4. Kaʻina paipu huinahā ʻole

Poe kila-tube billet-inspection-wela-piercing-sizing-hot rolling-flat head-inspection-pickling-spherical annealing-anu kiʻi-forming-Qikou- - ho'āʻo

Q345A:C≤0.20,Mn ≤1.70,Si≤0.50,P≤0.035,S≤0.035;

Q345B:C≤0.20,Mn ≤1.70,Si≤0.50,P≤0.035,S≤0.035;

Q345C:C≤0.20,Mn ≤1.70,Si≤0.50,P≤0.030,S≤0.030,Al≥0.015;

Q345D:C≤0.18,Mn ≤1.70,Si≤0.50,P≤0.030,S≤0.025,Al≥0.015;

Q345E:C≤0.18,Mn ≤1.70,Si≤0.50,P≤0.025,S≤0.020,Al≥0.015;

Q345A, B, C, D, E Nb≤0.07,V≤0.15,Ti≤0.20,Cr≤0.30,N≤0.012,Mo≤0.10. 20#, Q235B

| Pakaukau kikoo paipu huinahalike mānoanoa (mm) | ʻO ka papa kuhikuhi kikoʻī o ka paipu ʻāpana ʻāpana pāpaʻi mānoanoa (mm) | ||

| 16~34×0.4~2.0 | 380~500×380~500×8.0~30.0 | 10~20×20~40×0.6~12.0 | 250~300×100~250×6~30.0 |

| 16~34×0.4~2.0 | ʻO kekahi ʻōlelo kikoʻī hou e like me kēia | 20×50×1.0~2.0 | 400×250×8~30.0 |

| 38×38×1.0~4.0 | 550×550×10.0~40.0 | 22~40×35~100×0.9~5.0 | 400~×300×8~30.0 |

| 40~95×40~95×1.0~8.0 | 600~1000×600~1000×10.0~50.0 | 25×40×0.9~3.75 | 450~500×200~450×8~30.0 |

| 100×100×2.0~8.0 | 50×60×2.0~5.0 | ʻO kekahi ʻōlelo kikoʻī hou e like me kēia | |

| 120~350×120~350×4.0~30.0 | 50~200×60~150×2.0~12.0 | 600~1000×200~800×10~28.0 | |