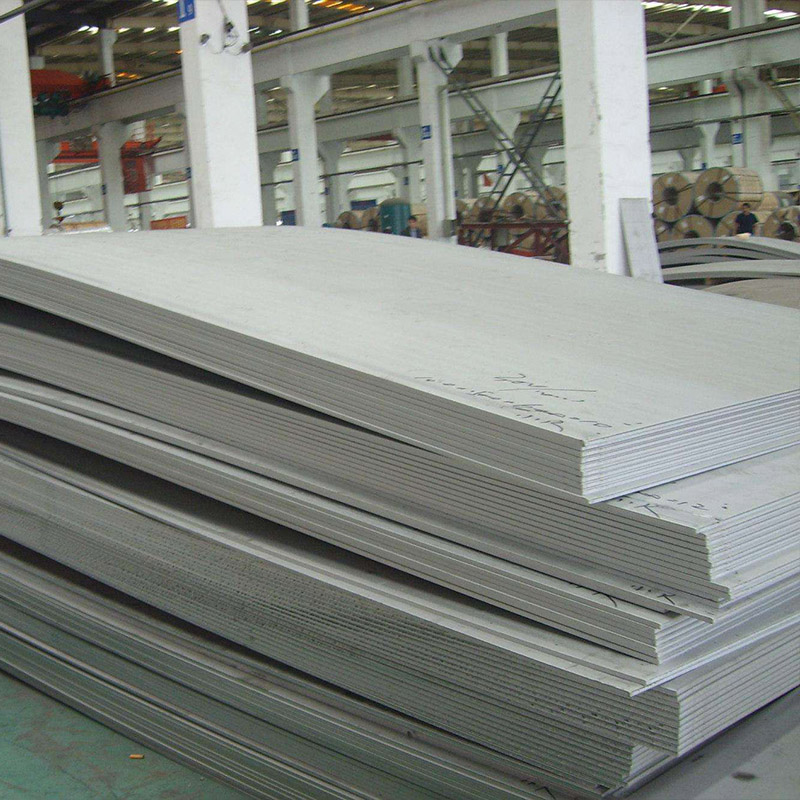

304 Pāʻani Kuhili ʻole

Papa: 300 moʻo

Kūlana: ASTM

Ka lōʻihi: Maʻamau

Mānoanoa: 0.3-3mm

Laulā: 1219 a maʻamau

Kumu: Tianjin, Kina

inoa inoa: jinbaicheng

Ke kumu hoʻohālike: pā kila kuhiliʻole

ʻAno: pepa, pepa

Hoʻohana: ka hoʻoluʻu a me ka hoʻonani ʻana i nā hale, nā moku a me nā ala kaʻa

Hoʻomanawanui: ± 5%

Nā lawelawe hana: kulou, wili, uncoiling, kuʻi a ʻokiʻoki

Papa kila: 301L, s30815, 301, 304n, 310S, s32305, 410, 204c3, 316Ti, 316L, 34,14j 321, 410S, 410L, 436l, 436l, 436l, 410L, 436l 314, 347, 430, 309S, 304, 439, 204c2, 425m, 409L, 4, 5, 30L, 4, 5, 30j2 444, 301LN, 305, 429, 304j

Lapaʻau ʻili: BA

Ka manawa hoʻouna: 8-14

Inoa Huahana: 304 pā kila kila

Kaʻina hana: ka'ōwili anuanu a me ka'ōwili wela

Ili: Ba, 2b, No.1, no.4,8k, HL,

Maka aniani: wili a ʻokiʻoki

Packaging: ʻO ke kiʻiʻoniʻoni PVC + ka pepa wai wai + ka pahu lāʻau fumigation

Laʻana: free sample

ʻO 430 ke kila kila he kila maʻamau me ka pale ʻana i ka corrosion maikaʻi. ʻOi aku ka maikaʻi o kāna conductivity wela ma mua o ka austenite, ʻoi aku ka liʻiliʻi o kāna coefficient o ka hoʻonui ʻana i ka wela ma mua o ka austenite, ka pale ʻana i ka luhi wela, ka hoʻohui ʻana i ka titanium element stabilizing, a me nā waiwai mechanical maikaʻi i ka weld. Hoʻohana ʻia ʻo 430 stainless steel no ke kūkulu hale ʻana, nā ʻāpana puhi wahie, nā mea hana hale a me nā mea hana hale. ʻO 430F kahi ʻano kila me ka hana ʻoki manuahi ma ke kila 430. Hoʻohana nui ʻia ia no nā lathes aunoa, bolts a me nā nati. Hoʻohui ʻo 430lx iā Ti a i ʻole Nb i ke kila 430 a hoʻemi i ka ʻike o C, e hoʻomaikaʻi ana i ka hana a me ka hana kuʻi. Hoʻohana nui ʻia ia i loko o ka pahu wai wela, ka ʻōnaehana wai wela, nā mea hoʻomaʻemaʻe, nā lako paʻa hale, nā uila uila, etc.

Papa ili

ʻO 430 ke kila kila ʻole nā mokuʻāina. ʻOkoʻa nā mokuʻāina like ʻole, ka pale lepo a me ke kūpaʻa corrosion.

No.1, 1D, 2D, 2b, N0.4, HL, Ba, aniani, a me nā mokuʻāina lapaʻau ʻē aʻe.

ʻenehana hana ʻano

1D - ka ʻili granular hoʻopau, ʻike ʻia hoʻi he ʻili noe. ʻenehana hana: ʻōwili wela + annealing, pana peening a pickling + ʻōwili anuanu + annealing a pickling.

2D - keʻokeʻo ʻālohilohi iki ke kālā. ʻenehana hana: ʻōwili wela + annealing, pana peening a pickling + ʻōwili anuanu + annealing a pickling.

2B - keʻokeʻo keʻokeʻo a ʻoi aku ka nani a me ka palahalaha ma mua o ka ʻili 2D. ʻenehana hana: ʻōwili wela + annealing, pana peening a pickling + ʻōwili anuanu + annealing a pickling + quenching a tempering rolling.

BA - ka nani o ka ʻili maikaʻi a me ka noʻonoʻo kiʻekiʻe, e like me ka ʻili o ke aniani. ʻenehana hana: ʻōwili wela + annealing, pana peening a pickling + ʻōwili anuanu + annealing a pickling + poli ʻili + hoʻopau a me ka ʻōwili ʻana.

NO.3 - loaʻa iā ia ka ʻōlinolino maikaʻi a me ka palaoa koʻikoʻi ma ka ʻili. ʻenehana hana: polishing a kinai ʻana a me ka tempering rolling o nā huahana 2D a i ʻole 2B me 100 ~ 120 mau mea abrasive (JIS R6002).

NO.4 - maikaʻi kona nani a me nā laina maikaʻi ma ka ʻili. ʻenehana hana: polishing a quenching a tempering rolling of 2D or 2B with 150 ~ 180 abrasive material (JIS R6002).

HL - hina hina me ka lauoho lauoho. ʻenehana hana ʻenehana: Nā huahana Polish 2D a i ʻole 2B me nā mea abrasive me ka nui o nā ʻāpana kūpono e hōʻike i ka ʻili i nā laina wili mau.

Mirro - kūlana aniani. ʻenehana hana: wili a hoʻolalelale i nā huahana 2D a i ʻole 2B me ka nui o nā mea wili liʻiliʻi kūpono i ka hopena aniani.

430 kuhiliʻole kila i ka hiki o ka oxidation kū'ē i corrosion, akā, i ka manaʻo o intergranular corrosion.

Hoʻohana nui ʻia ʻo 430 uea kila kila ma ke axis.

No ka mea he palekana a ʻaʻohe mea ʻawaʻawa, hoʻohana nui ʻia ia i ka papa ʻaina meaʻai.

austenite

301,302, 303, 303se, 304, 304L, 304N1, 304N2, 304LN, 305, 309S, 310S, 316, 316L, 316N, 316J1, 316J1L, 317J1L 321, 347, XM7, XM15J1, 329J1

Ferrite

405, 430, 430F, 434, 447J1, 403

Martensite

410, 410L, 405, 416, 410J1, 420J1, 420J2, 420F, 431, 440A, 440B, 440C, 440F, 630, 631, 632

Aia kekahi ʻano o ke kila kila, 201, 202, 203 a me 204, nona ka chromium haʻahaʻa a me ka manganese kiʻekiʻe (hoʻonui ka ikehu chromium kiʻekiʻe i ka corrosion, a hiki i ka manganese kiʻekiʻe ke hana i ka mea non-magnetic). ʻAʻole maikaʻi ke kūpaʻa corrosion o kēia ʻano kila kila a hoʻohana mau ʻia no ka hoʻonani ʻana i ka ʻāina maloʻo.

| Ili | Nā hiʻohiʻona | Hōʻuluʻulu o nā ʻano hana | Ke kumu |

| NO.1 | Makeke keʻokeʻo kala | ʻōwili wela i ka mānoanoa i ʻōlelo ʻia | E hoʻohana me ka ʻole o ka ʻili |

| NO.2D | Keʻokeʻo kala | ʻO ka mālama ʻana i ka wela a me ka pickling ma hope o ka ʻōwili anu | Mea maʻamau, mea kiʻi hohonu |

| NO.2B | ʻOi aku ka ikaika o ka nani ma mua o No.2D | Ma hope o ka mālama ʻana i ka No.2D, lawe ʻia ka ʻōwili anuanu hope loa ma o ka wili polishing | Laau nui |

| BA | Alohilohi e like me ke aniani | ʻAʻohe mea maʻamau, akā ʻo ia ka mea maʻamau i ka hana ʻana i ka ʻili o ka annealed, me ka ʻike kiʻekiʻe. | Nā mea kūkulu hale, nā lako kīhini |

| NO.3 | Ka wili ʻana | E wili me 100 ~ 200# (unit) kāʻei abrasive | Nā mea kūkulu hale, nā lako kīhini |

| NO.4 | wili waena | ʻO kahi ʻili polima i loaʻa ma ka wili ʻana me ka lipine abrasive 150~180 # | ʻO Ditto |

| NO.240 | ʻO ka wili maikaʻi | E wili ana me ke kāʻei abrasive 240# | lako kīhini |

| NO.320 | ʻO ka wili maikaʻi loa | E wili ana me ke kāʻei abrasive 320# | ʻO Ditto |

| NO.400 | Alohilohi kokoke i ka ba | E wili me 400# huila poli | Nā mea maʻamau, nā mea kūkulu hale, nā lako kīhini |

| HL | wili lauoho | Nui nā ʻāpana wili i ka laina lauoho wili (150 ~ 240 #) me nā mea ʻāpana kūpono. | Nā mea kūkulu hale |

| NO.7 | Kokoke i ka wili aniani | ʻO ka wili me 600# rotary polishing huila | No ke kiʻi a me ke kāhiko |

| NO.8 | wili aniani | ʻO ke aniani i hoʻoheheʻe ʻia me ka huila poli | Reflector, mea hoʻonani |