1. ʻAʻahu-kū pale kila ka nānā 'ana

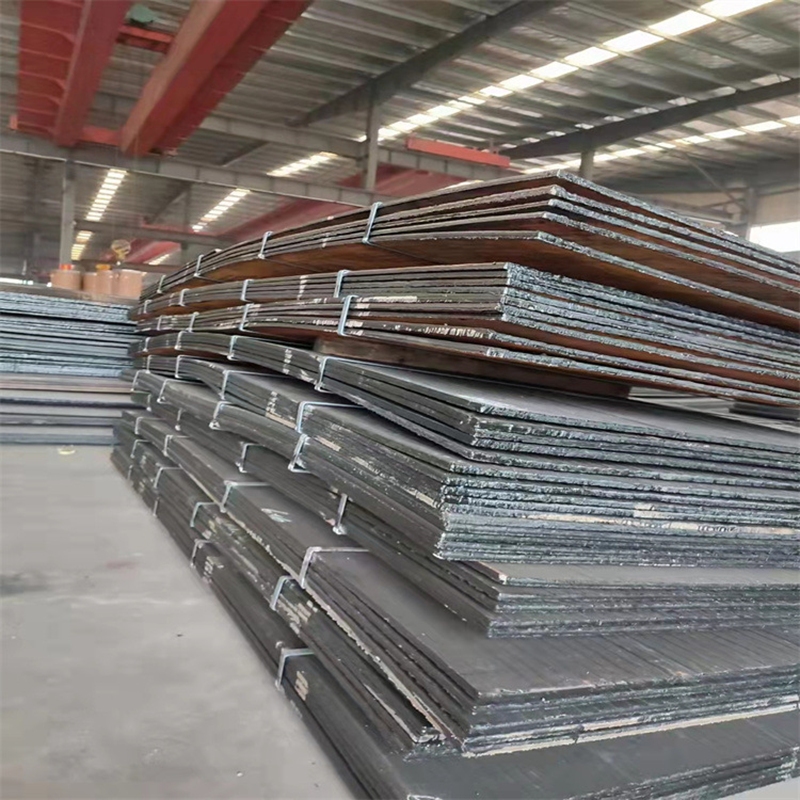

ʻO ka Wear Resistant Steel Plate, ʻo ia hoʻi ka pā kila kūʻokoʻa, he huahana pākuʻi kūikawā i hoʻohana kūikawā ʻia ma lalo o nā kūlana hana o nā ʻāpana nui. Hoʻokumu ʻia ia me ka pā hao hao haʻahaʻa a me ka ʻāpana pale ʻaʻahu.

Loaʻa i ka pā kila kila nā hiʻohiʻona o ka ikaika kiʻekiʻe a me ke kūpaʻa kiʻekiʻe. He 1/3 a hiki i ka 1/2 o ka mānoanoa a pau o ke kapa komo pale. I ka wā e hana ai, hāʻawi ka matrix i nā waiwai piha e like me ka ikaika, ka paʻakikī a me ka plasticity e kūʻē i nā ikaika o waho, a ʻo ka ʻāpana pale pale pale e hāʻawi i ka pale lole e hoʻokō i nā koi o nā kūlana hana i kuhikuhi ʻia.

Nui nā ʻano ʻano o nā pā kila pale ʻaʻahu, e komo pū me nā pā kila a me nā pā kila hoʻopaʻa ʻia. No ka laʻana, KN60 ʻaʻahu pale kila he ʻano huahana i hana ʻia e ka hoʻohui ʻana i kekahi mānoanoa o ka ʻāpana pale pale me ka paʻakikī kiʻekiʻe a me ke kūpaʻa maikaʻi loa ma ka ʻili o ke kila haʻahaʻa haʻahaʻa a i ʻole ke kila haʻahaʻa me ka paʻakikī maikaʻi. a me ka plasticity ma ke ʻano o ka ʻili. ʻO nā ʻenehana ʻenehana o KN60 paʻa paʻa paʻa kila penei: ʻo ka paʻakikī Vickers ʻo 1700HV; ʻO ka mea haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa, a hiki ke hāʻawi ʻia nā ʻano mea ʻē aʻe o ka hoʻoheheʻe ʻana i nā alloys paʻakikī a me ka niobium carbide e like me nā koi. He waiwai ka chromium a me ka boron alloy carbide; ʻo ka paʻakikī o ka papa hoʻopaʻa ʻaʻahu i hui pū ʻia ʻo C62-65 HRc; ʻo ka mānoanoa he 3 - 15 millimeters; ʻoi aku ka nui o ka mea paʻa paʻa ma mua o 50%; ʻO ka mahana hana kiʻekiʻe loa he 1000 ° C.

Eia kekahi, ʻo ka pā kila kila 360 kekahi ʻano o ka pā ikaika kiʻekiʻe a me ka paʻa kiʻekiʻe. Hana ʻia ia e ka ʻenehana prestressing a ʻoi aku ka maikaʻi o ka tensile ikaika a me ka ikaika compressive, a me ke kūpaʻa ʻaʻahu maikaʻi a me ke kūpaʻa hopena.

2. Hoʻohana ʻana i nā pā kila kila

2.1 Ka laulā o nā noi ʻoihana

Loaʻa i nā papa kila pale lole i nā noi nui i nā ʻoihana like ʻole. I ka ʻoihana metallurgical, hoʻohana ʻia lākou i nā mea hana e like me nā crushers a me nā kāʻei conveyor, i hoʻokau mau ʻia i ka abrasion a me ka hopena. I ka ʻoihana lanahu, hoʻohana ʻia lākou i nā chutes lanahu a me nā ʻāpana mīkini mining e kū i nā kūlana paʻakikī. Hoʻohana ʻia ka ʻoihana sima i nā papa kila pale ʻaʻahu i nā kiln a me nā wili wili e hōʻoia i ka lōʻihi o ka lawelawe ʻana. I ka ʻoihana mana, hoʻohana ʻia lākou i nā pulverizers lanahu a me nā ʻōnaehana lawelawe lehu.

No ka laʻana, hoʻohana nui ʻia ka pā kila 360 i nā kahua e like me nā kaʻa, nā alahao, nā mokulele, nā metallurgy, nā ʻoihana kemika, nā mīkini, ka ʻaila, ka uila, ka mālama wai, a me ke kūkulu ʻana. He mea kūpono ia no nā ʻāpana e halihali ana i nā ukana hopena nui i nā mīkini ʻenehana ma muli o kona kūpaʻa maikaʻi ʻana i ka lole, ke kūpaʻa hopena, a me ke kūpaʻa corrosion.

2.2 Kiʻekiʻe kumu kūʻai-pono

Ke hoʻohālikelike ʻia me nā mea ʻē aʻe, hāʻawi nā papa kila-pale i ka hana kiʻekiʻe. ʻOiai ʻoi aku ka kiʻekiʻe o ke kumu kūʻai mua o nā pā kila ma mua o kekahi mau mea kuʻuna, ʻoi aku ka maikaʻi o ko lākou pale ʻana i ka ʻaʻahu a me ka lōʻihi i ka hopena o ka mālama ʻana i ka wā lōʻihi. No ka laʻana, ʻo kahi ʻoihana e hoʻohana ana i nā pā kila pale lole i kāna kaʻina hana e hōʻemi i ka manawa haʻahaʻa no ka mālama ʻana a me ka hoʻololi ʻana i nā lako, e alakaʻi ana i ka hoʻonui ʻana i ka huahana a me ka mālama kālā.

Wahi a ka ʻikepili, ʻoi aku ka lōʻihi o ke ola lawelawe o nā pā kila kila ma mua o nā papa kila maʻamau. ʻO ia ke ʻano e hiki i nā ʻoihana ke hōʻemi i kā lākou kumukūʻai waiwai a me nā koina mālama i ka manawa. Hoʻohui ʻia, ʻo ka hana maikaʻi loa o nā pā kila pale ʻaʻahu e hōʻemi i ka hopena o ka hemahema o nā lako hana a me nā lohi o ka hana ʻana, e hoʻonui hou i kā lākou mau pono waiwai. ʻO ka hopena, ʻoi aku ka nui o nā ʻoihana a me nā mea hana e hōʻike ana i kahi makemake no nā pā kila kila.

3. Ka hoʻokaʻawale ʻana o nā mea ʻaʻahu-kūpono i nā pā kila

3.1 Nā ʻano mea maʻamau

Hana ʻia nā pā kila kūʻokoʻa ma ka hoʻoheheʻe ʻia ʻana o nā ʻāpana pale ʻaʻahu ma luna o ka ʻili o ke kila haʻahaʻa haʻahaʻa a i ʻole ke kila haʻahaʻa. Aia kekahi mau papa kila a me nā pā kila i hoʻopaʻa ʻia. No ka laʻana, hana ʻia ka pā kila kila ma ka hoʻohui ʻana i kekahi mānoanoa o ka ʻaʻahu paʻa paʻa me ka paʻakikī kiʻekiʻe a me ke kūpaʻa maikaʻi loa ma ka metala kumu.

3.2ʻO nā ʻano ʻano like ʻole

ʻEkolu mau ʻano o nā pā kila pale ʻaʻahu: ke ʻano maʻamau, ke ʻano pale hopena, a me ke ʻano pale wela kiʻekiʻe.

Loaʻa ka hana kūpaʻa a kūpono i nā kūlana ʻaʻahu maʻamau. Loaʻa iā ia ka pale ʻaʻahu maikaʻi a me ka ikaika haʻahaʻa. Hiki i nā ʻāpana ʻenehana ke komo i kahi pae paʻakikī, ma kahi o 50-60 HRC. Loaʻa i ka haku mele nā mea e like me ka chromium a me ka manganese e hoʻomaikaʻi i ke kūpaʻa ʻaʻahu. I ka hana, hiki iā ia ke kū i kahi pae o ka abrasion a hoʻohana nui ʻia i nā ʻoihana e like me ka hana ʻana i nā mīkini.

Ua hoʻolālā ʻia ka pā kila e kū i nā hopena koʻikoʻi. Loaʻa iā ia ka paʻakikī kiʻekiʻe a me ke kūpaʻa hopena maikaʻi loa. Loaʻa pinepine ka mea i nā mea hao e hoʻonui ai i kona pale ʻana i ka hopena. No ka laʻana, hiki i kekahi mau pā kila a hiki ke pale i ka hopena ma kahi o 45-55 HRC akā me ke kūpaʻa ʻoi aku ka hopena. He kūpono kēia ʻano no nā noi kahi e hoʻopili pinepine ʻia ai nā mea hana, e like me ka ʻoihana mining a me ke kūkulu hale.

Hiki ke pale i nā wela kiʻekiʻe i ka pale kila kū'ē i ka wela. Hanaʻia ia me nā mea hoʻoheheʻe kūikawā e hiki ke mālama i ka paʻa i nā mahana kiʻekiʻe. Hiki i nā ʻāpana ʻenehana ke hoʻokomo i kahi mahana hana kiʻekiʻe a hiki i 800-1200°C. Loaʻa i ka haku mele nā mea e like me ka nickel a me ka chromium e hōʻoia i ka pale ʻana i ka wela kiʻekiʻe. I ka hana, hoʻohana nui ʻia ia i nā wahi wela kiʻekiʻe e like me nā kapuahi a me nā kiln i ka ʻoihana metallurgical a me ka sima.

Ka manawa hoʻouna: ʻOkakopa-31-2024